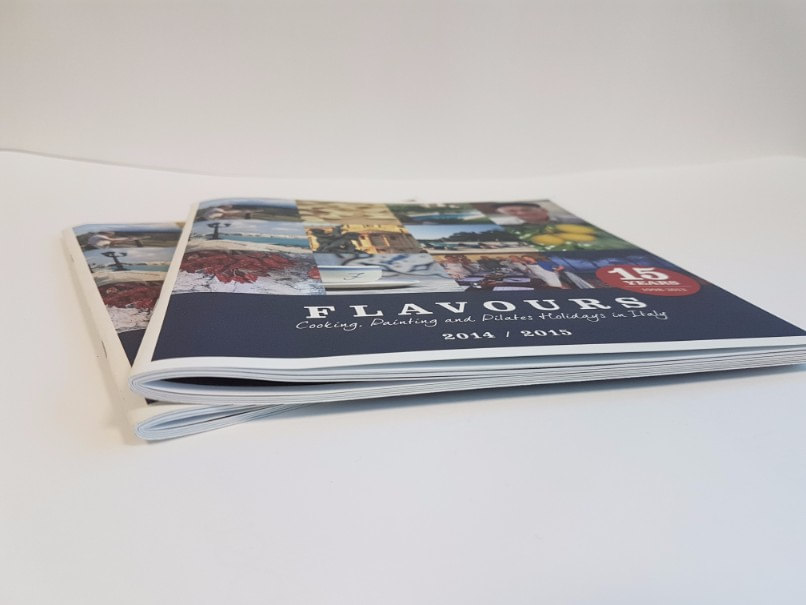

Offset Printing

Offset printing also called offset lithography.

It's a commonly used printing technique in which the image is transferred from a plate to a rubber blanket, then to the printing surface. It is one of the most popular printing methods used for printing books, catalogues, brochures, magazines.

Compared to other printing techniques - offset is better for high-quality big print runs. Offset printing gives you the highest print quality and it is much cheaper with a large print run.

There are many possibilities in product material choice and printing:

Colours: CMYK and Pantones;

Different types of coated, uncoated, art paper.

Digital Printing

In this type of production printable materials are delivered to the device in computer data. It is commonly used when offset is not cosst effective. In this type of print you can personalize your designs.

The order can be realized immediately and the print quality is close to the offset.

Print speed is faster than typical computers printers, but slightly slower than offset printing.

It is possible to print on many different substrates and in a wide range of weights.

-

Saddle-stitched

-

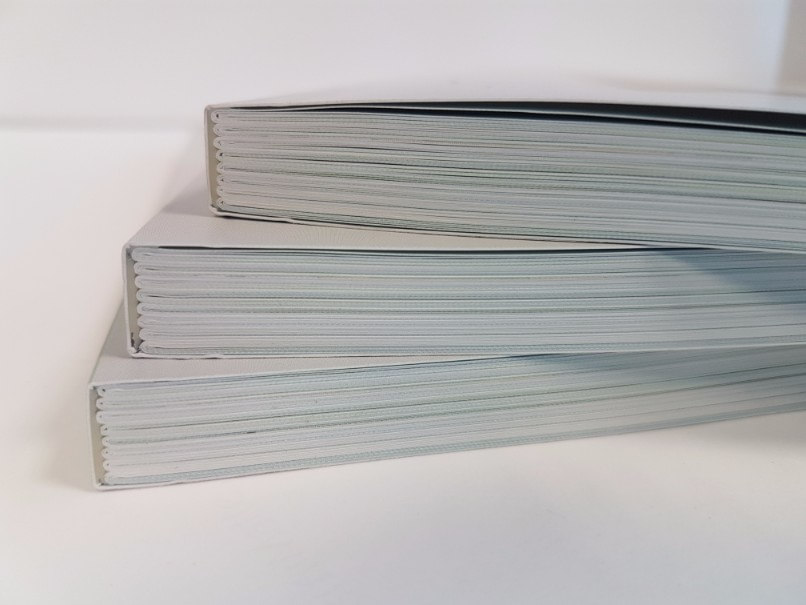

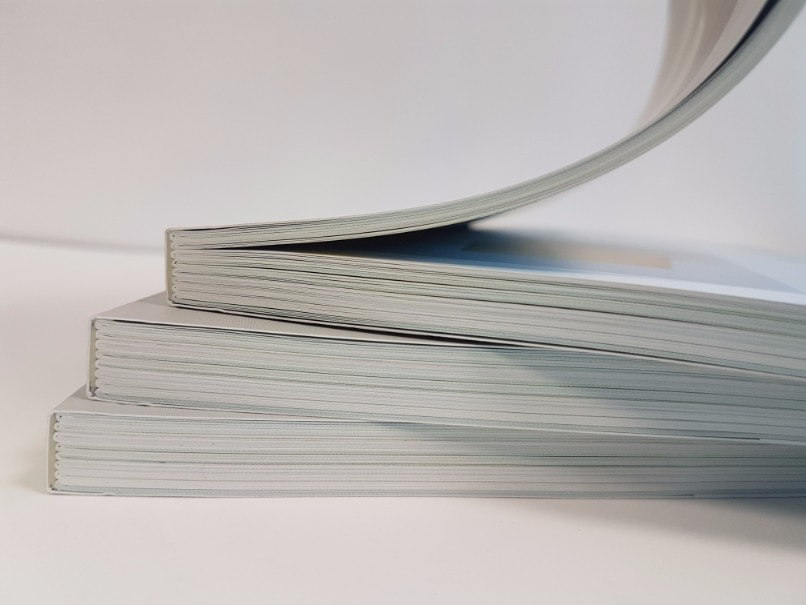

Soft cover Hotmelt and PUR binding

-

Soft cover glued/sewn with flaps

-

Soft cover sewn binding

-

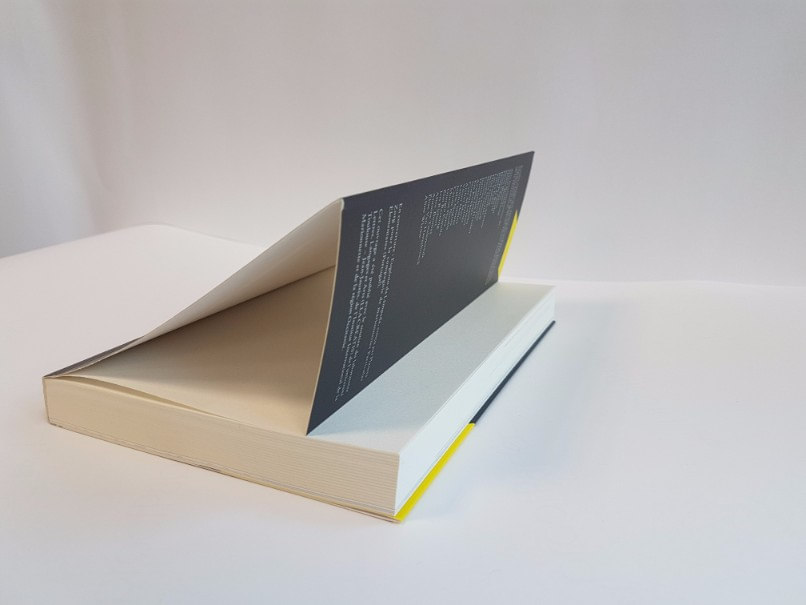

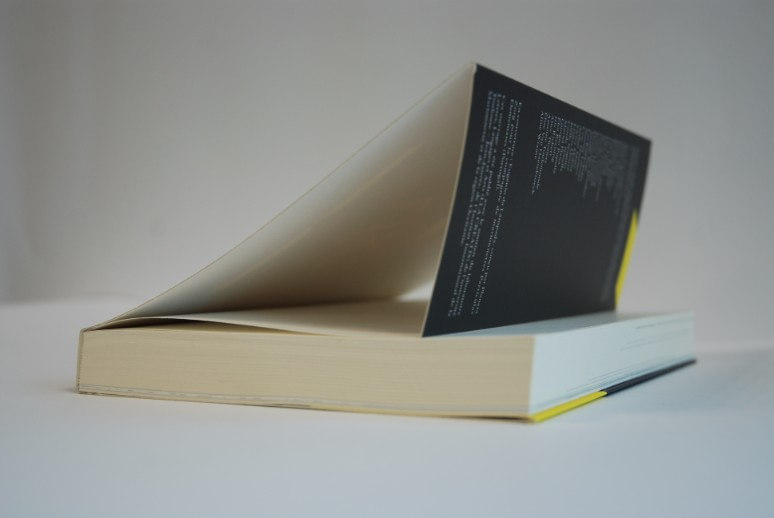

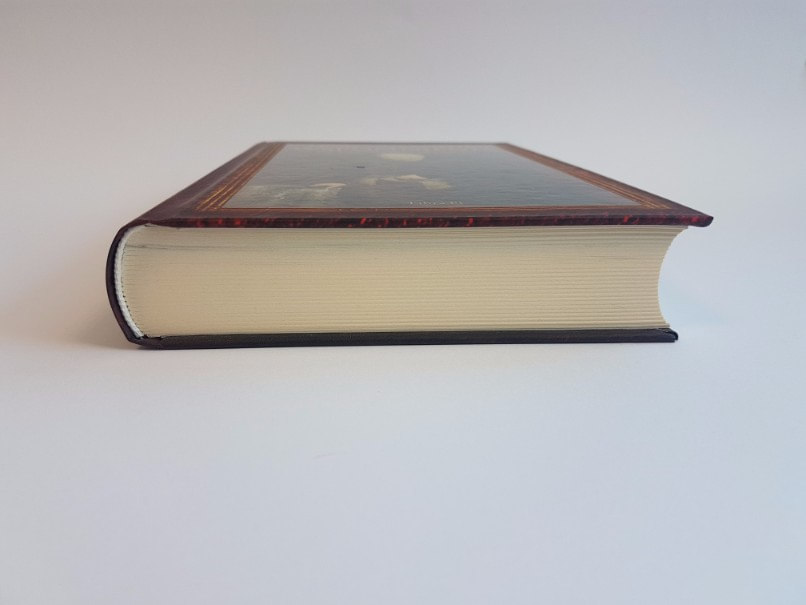

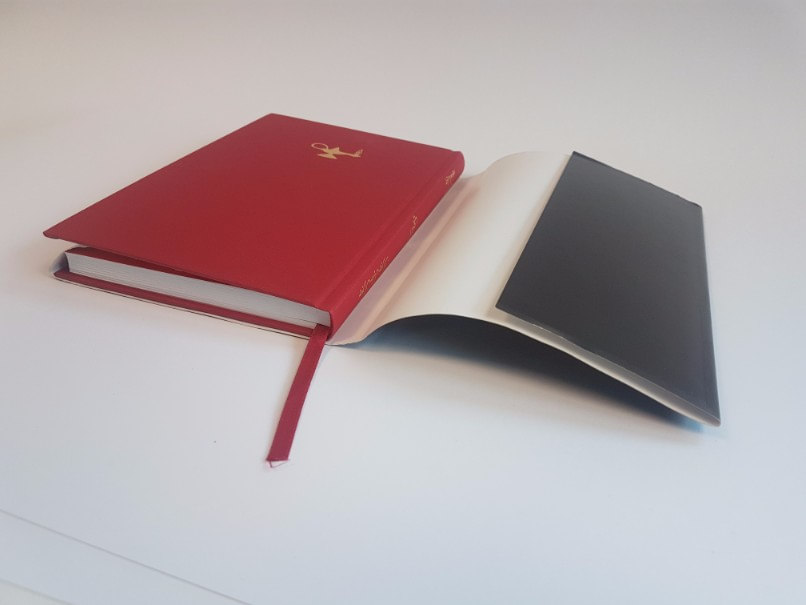

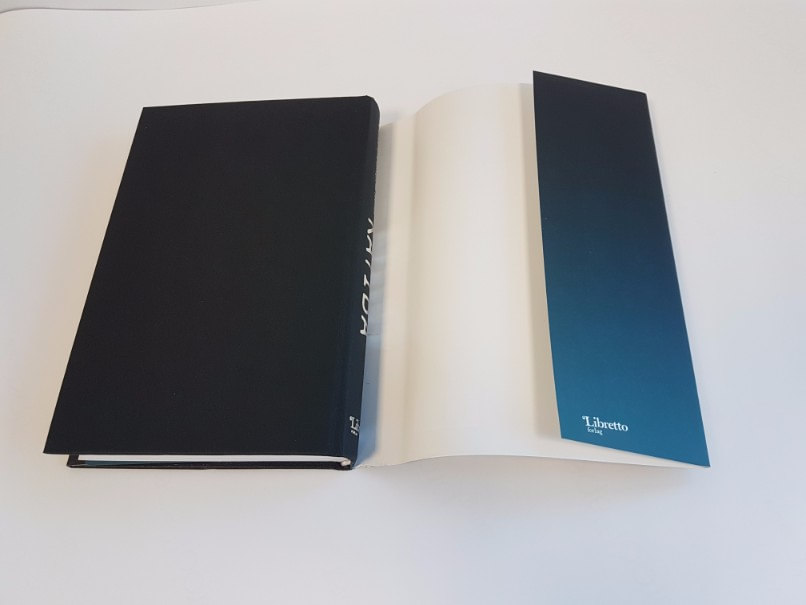

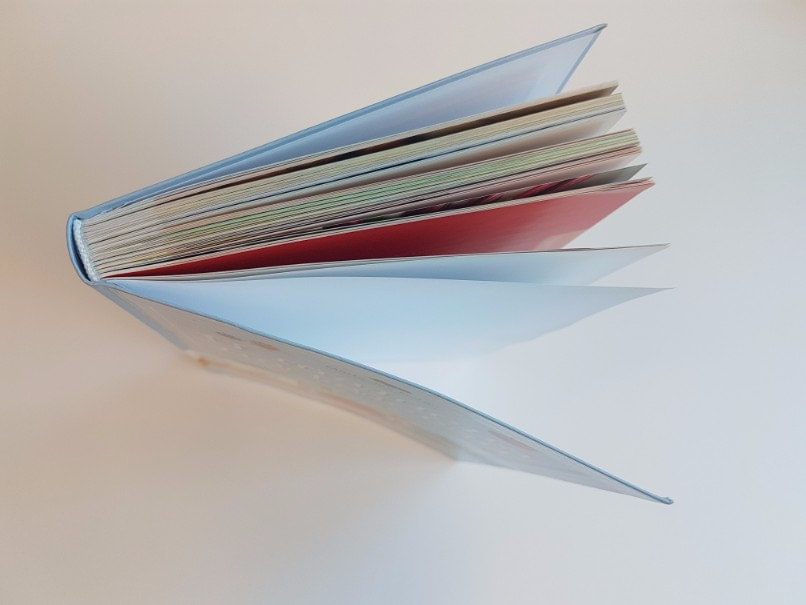

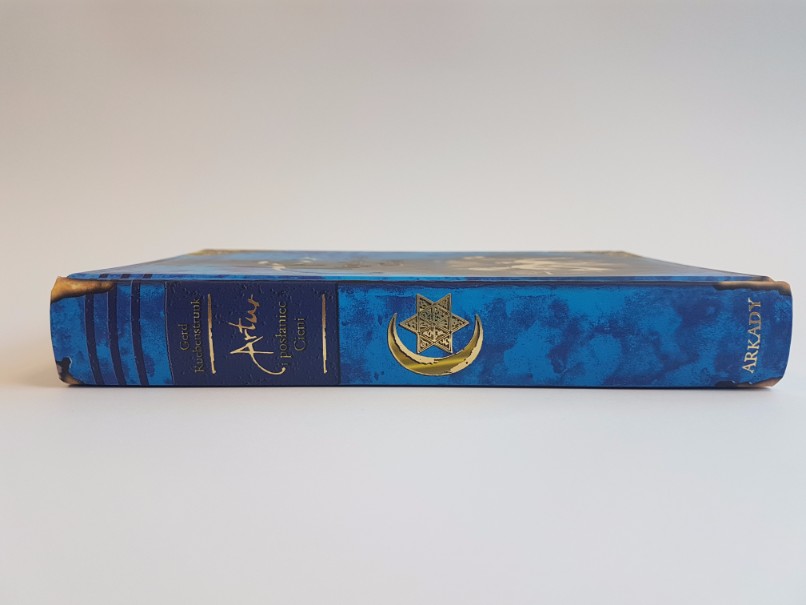

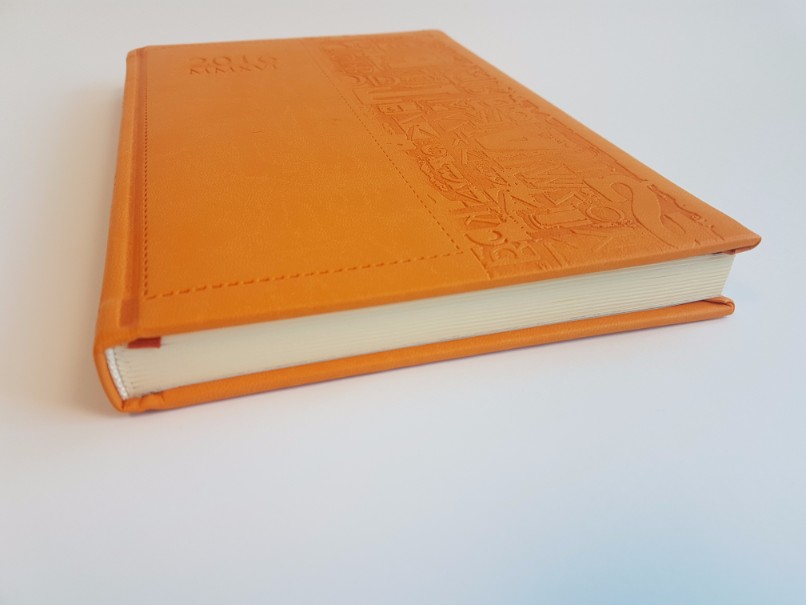

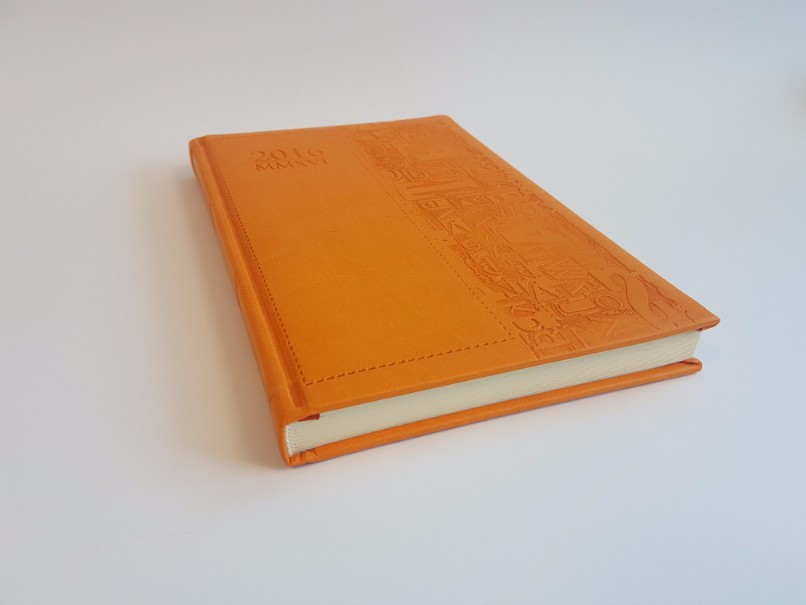

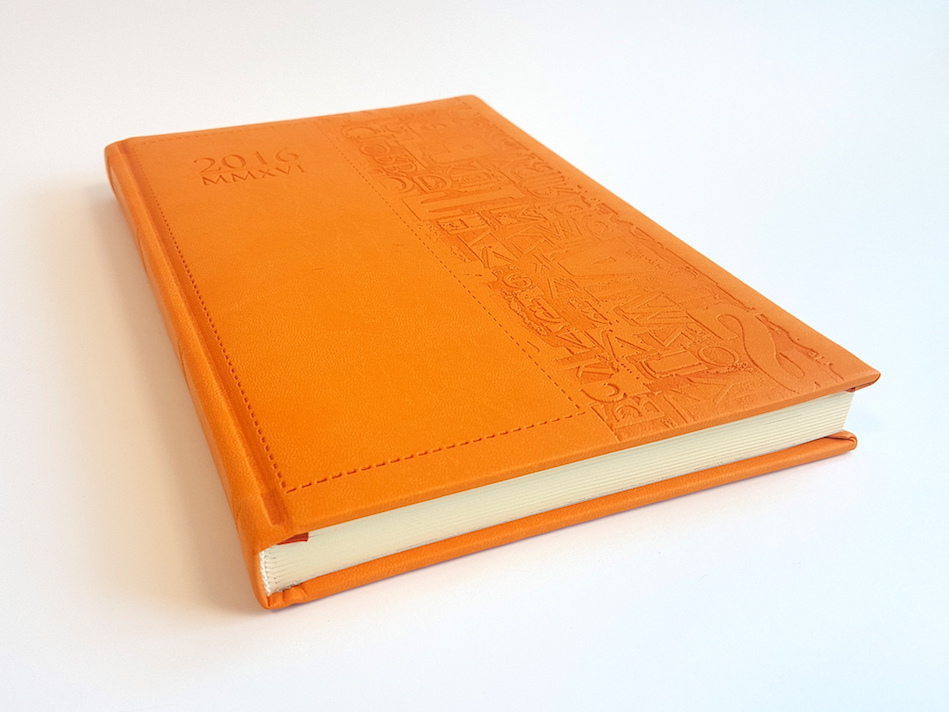

Hard cover sewn or PUR glued

-

Hard cover sewn or glued with dust jacket

-

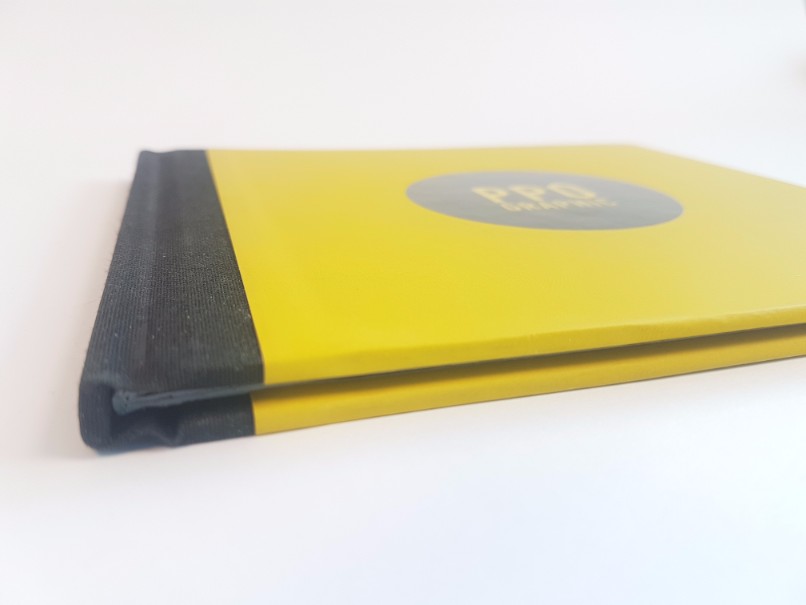

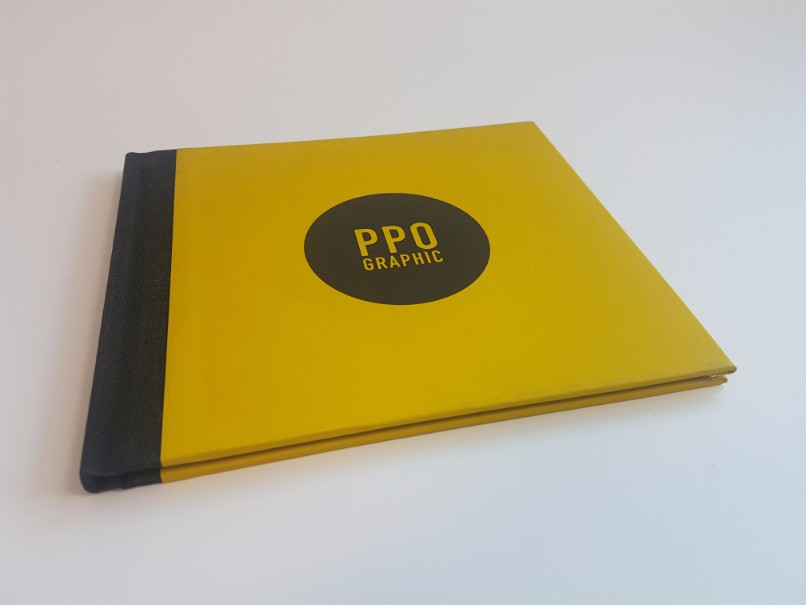

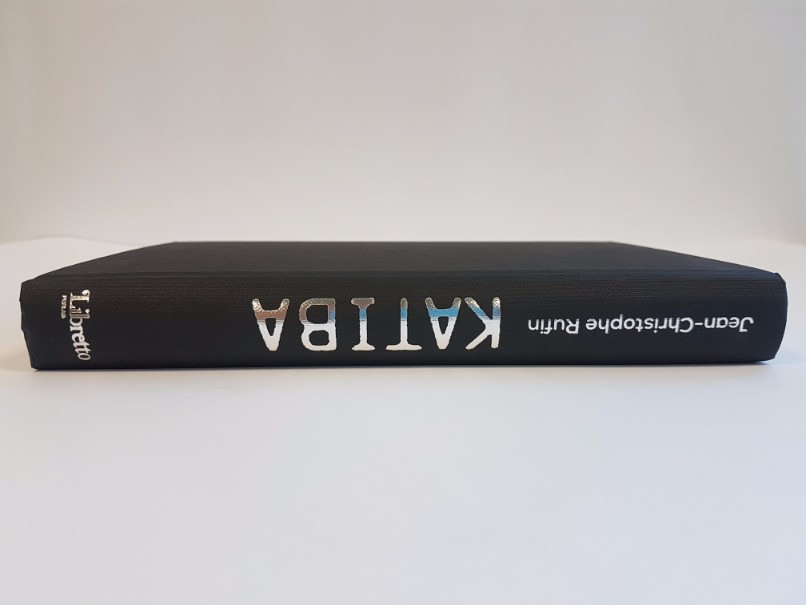

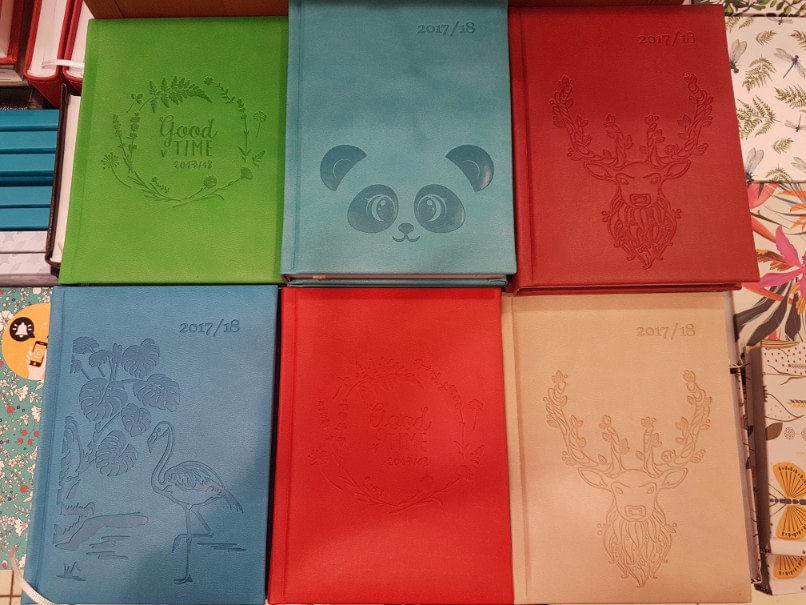

Hard cover with Geltex, fabric or leather

-

Hardcover binding with foam covers

-

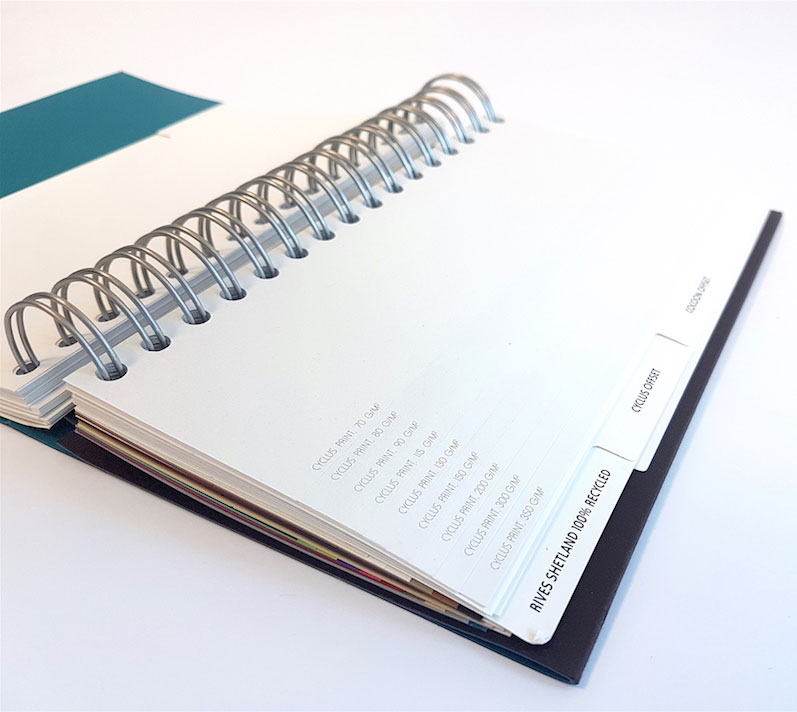

Wire binding/spiral binding

-

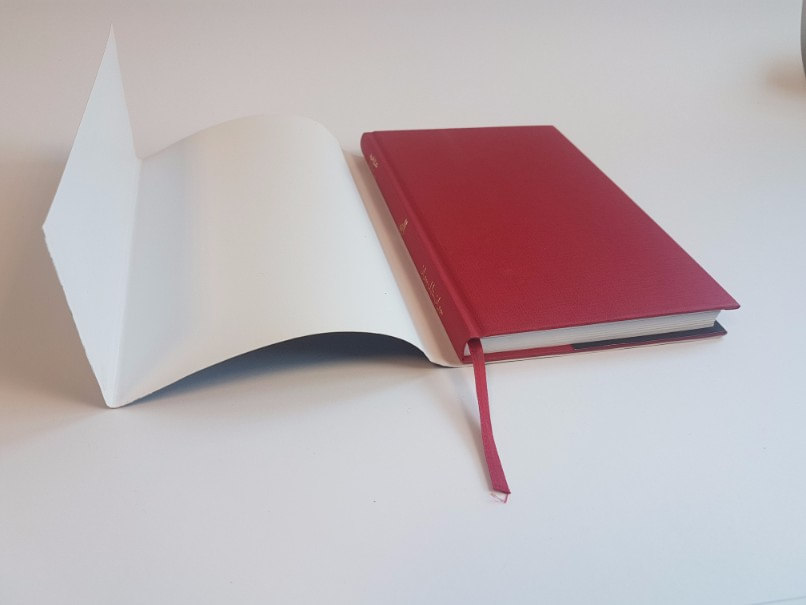

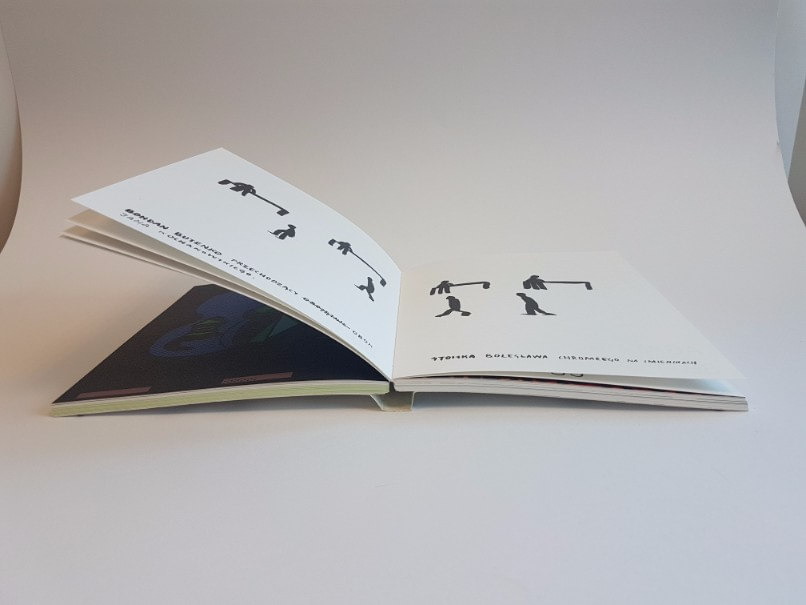

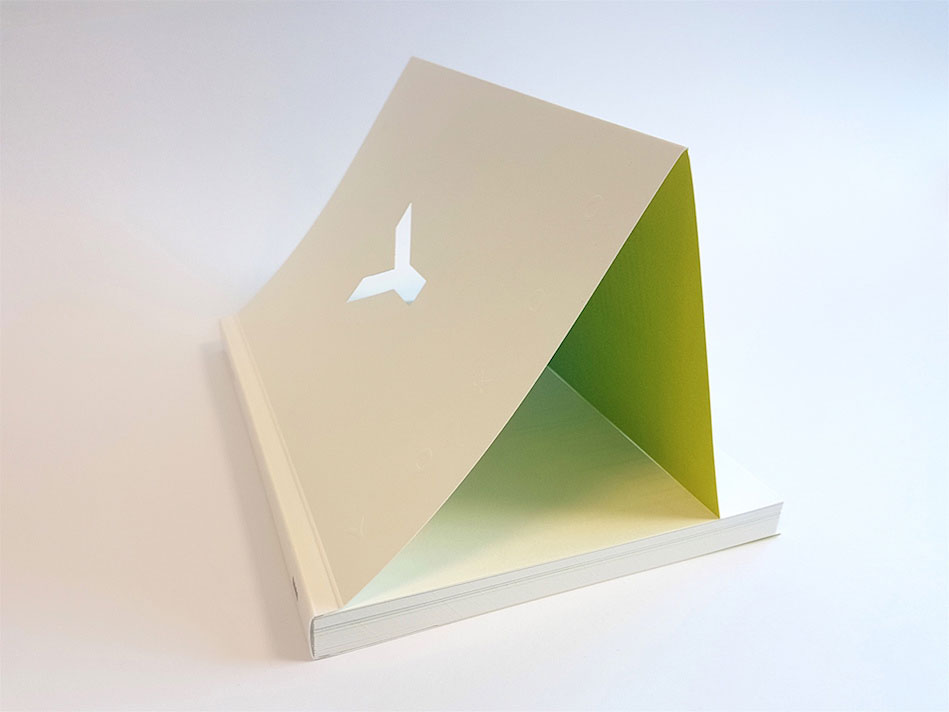

Integral binding sewn

-

Swiss binding

Pages are bind by a wire. A similar solution is a Case-in Wiro binding, where the spiral is not visible outside.

-

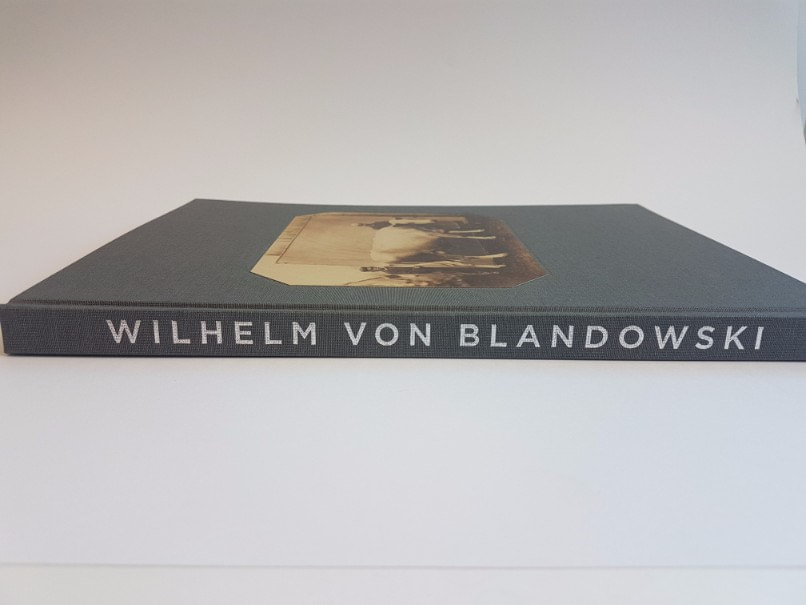

Half linen binding

-

Cerlox Binding

-

Otabind binding

FINISHES

There are free most used finishing types: varnish, lamination and embossing (hot-stamping).

Paper varnishes and foil (lamination) are applied to paper stock and gives the page a smooth and consistent texture as well as having the added benefit of sealing the printed material to help preserve it better.

High-quality books and magazines usually have a paper varnish applied to their pages.

There are many different ways to express uniqueness of project. You can use different types of lamination, foil, varnish, emboss to consist texture and printed colours emboss or make it more beautiful.

Varnish

-

Standard gloss / matt

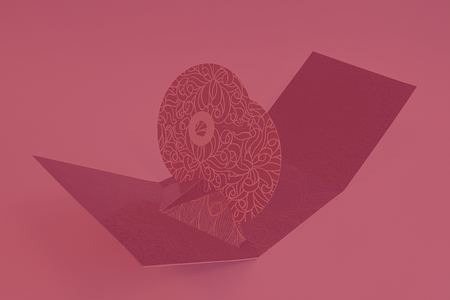

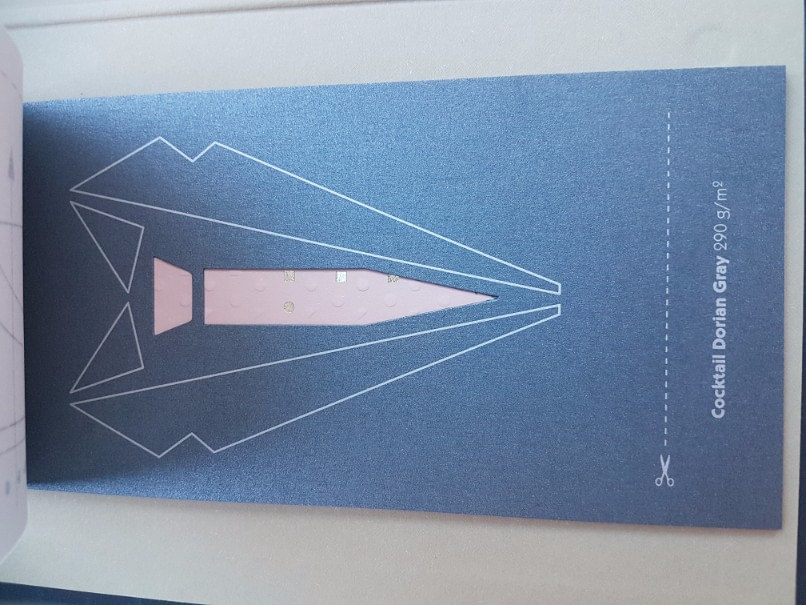

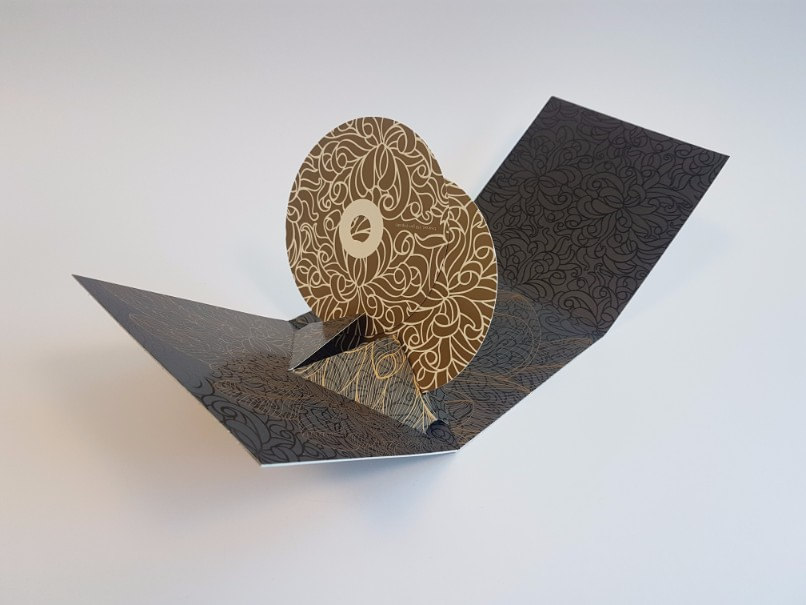

Die Cutting

-

Round corners

-

Shape cutting

-

Index tabs cutting

-

Perforating

Special materials for covers

-

Geltex / Wibalin cover materials

-

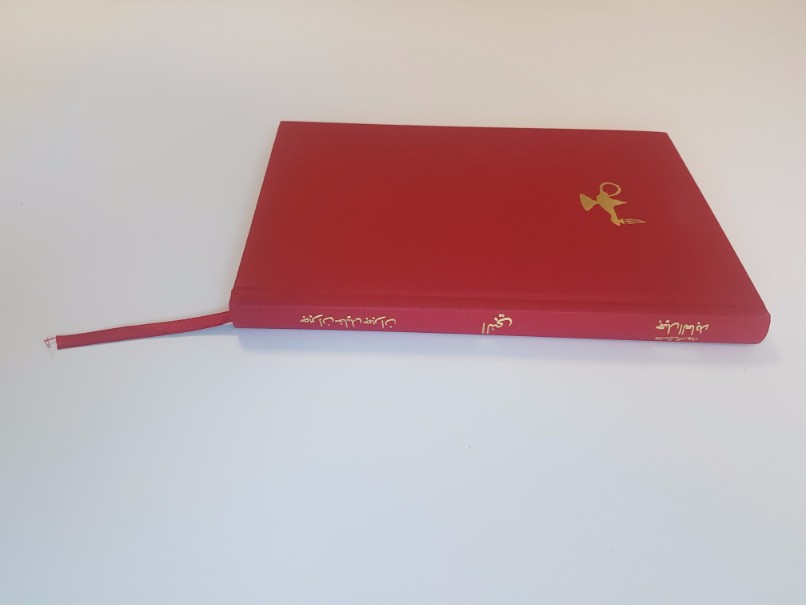

Natural leathers with option of embossing

-

Artificial leathers with option of embossing

-

Wooden covers

Other

-

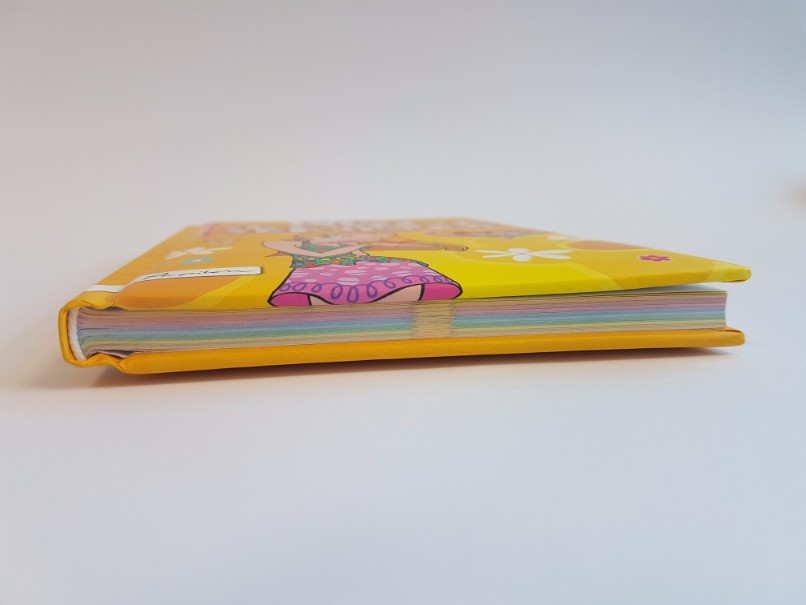

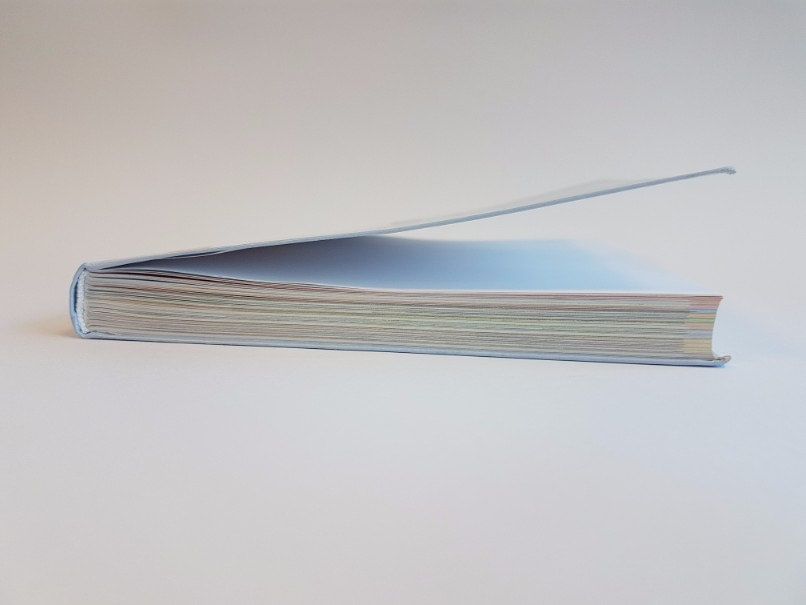

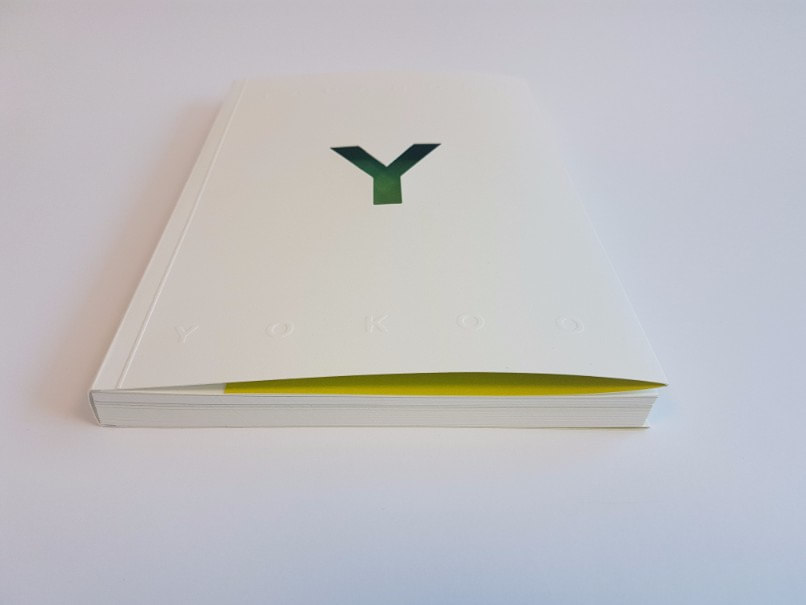

Coloured edges - painted or foiled

-

Scented paper & Fragrant B]books

-

Pasteboard cases for one or more books

-

Personalization

The safest, most secure form of binding. The sides are sewn or glued along the back.